We receive many inquiries from designers and engineers who are looking for an ‘industrial hook and loop’ solution. It’s clear that Halco has both the product range and the custom manufacturing capabilities to provide these higher performing closure solutions. But what makes industrial hook and loop different than just a conventional hook and loop closure and why is it important to understand? This blog article provides insight into the important aspects of an industrial hook and loop closure system.

Industrial hook and loop is specifically designed to meet the demands of heavy-duty and high-performance applications in various industries. While both industrial and regular hook and loop share the same basic concept of interlocking hooks and loops for fastening, there are several key differences that set industrial hook and loop apart:

- Strength and Durability: Industrial hook and loop is engineered to withstand greater forces and stresses compared to regular hook and loop. It is designed to hold up under heavy loads, repetitive use, and challenging environmental conditions.

– Halco helps you design the engagement strength and cycle life of a closure system with a comprehensive portfolio of specialty hook and loop materials. Our line of plastic molded hook products often is a solution to meet specific load bearing requirements. - Adhesive Options: Industrial hook and loop often comes with stronger and more resilient adhesive backing. This adhesive is formulated to adhere to a wider range of surfaces, including rough or uneven surfaces, and to maintain its hold over time.

– One of Halco’s core areas of expertise is the selection and use of adhesive systems to securely attach a hook and loop fastener to a substrate. We have both standard pre-coated adhesives and specialty pressure sensitive adhesives that we custom laminate. See our adhesives selection guide.

- Integration to Other Materials and Parts: Industrial hook and loop often needs to be integrated another part that then becomes a subassembly.

– Halco provides custom manufacturing services to attach hook and loop closures to other materials, like engineered foams and plastic parts that enhance design and speed speed assembly. See our converting capabilities page. - Temperature and Environmental Resistance: Industrial hook and loop is often designed to be more resistant to extreme temperatures, moisture, chemicals, UV exposure, and other environmental factors that could degrade its performance over time.

– Halco provides a range of solutions to meet the demands of UV exposure, moisture, temperature and flame resistance. - Regulatory and Industry Compliance: Industrial hook and loop may need to meet specific industry standards or regulations, depending on the application. This could include requirements related to flame resistance, electrical conductivity, or other safety considerations.

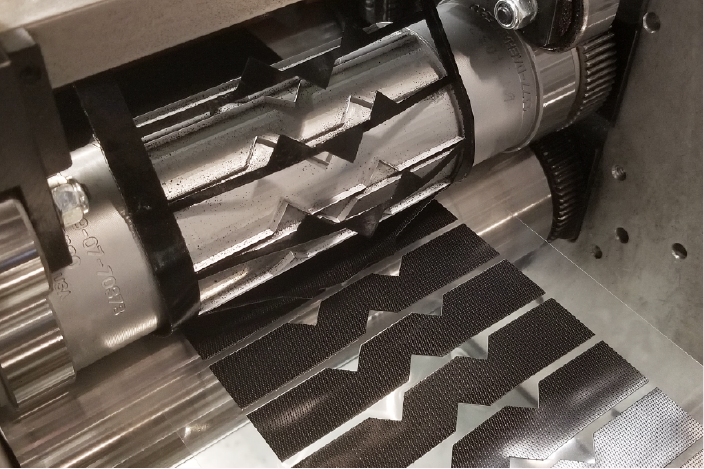

– Halco’s closure and fastening systems solutions meet a variety of industry specifications and compliance requirements. Speak to a representative to learn more or visit here to see a short list of some of the specs we already meet. - Customization: Industrial hook and loop can often be customized to meet specific requirements. This might involve creating specialized shapes, sizes, colors, or adhesive options to suit unique industrial needs.

– Halco is a custom manufacturer and fabricator of hook and loop closure systems and parts. This often takes the form of a custom strap, tab or kiss-cut parts on a roll. Services provided may include sewing, welding, adhesive lamination, die-cutting and printing.

In essence, the primary differences between industrial hook and loop and regular hook and loop lie in their design, materials, strength, durability, and suitability for demanding applications. Industrial hook and loop is engineered to provide a more robust and reliable fastening solution for heavy-duty and industrial settings, where regular hook and loop might not be able to meet the same performance standards.

Request a Sample and tell Us about your project