Automotive Hook and Loop

Specialty automotive fasteners for automotive interiors, insulation and wire harness management

custom Automotive fastening solutions

Halco is a trusted supplier of specialty automotive fasteners for automotive OEMs, tier suppliers and aftermarket product manufacturers. Many of the applications for which we provide fastening design expertise are related to automotive interior components and products. Our unique expertise is the integration of specialty hook and loop materials, custom adhesives that meet automotive requirements and custom plastic parts. We also have expertise in the converting of 3M Dual Lock, which is a frequently used reclosable fastening solution in the automotive industry.

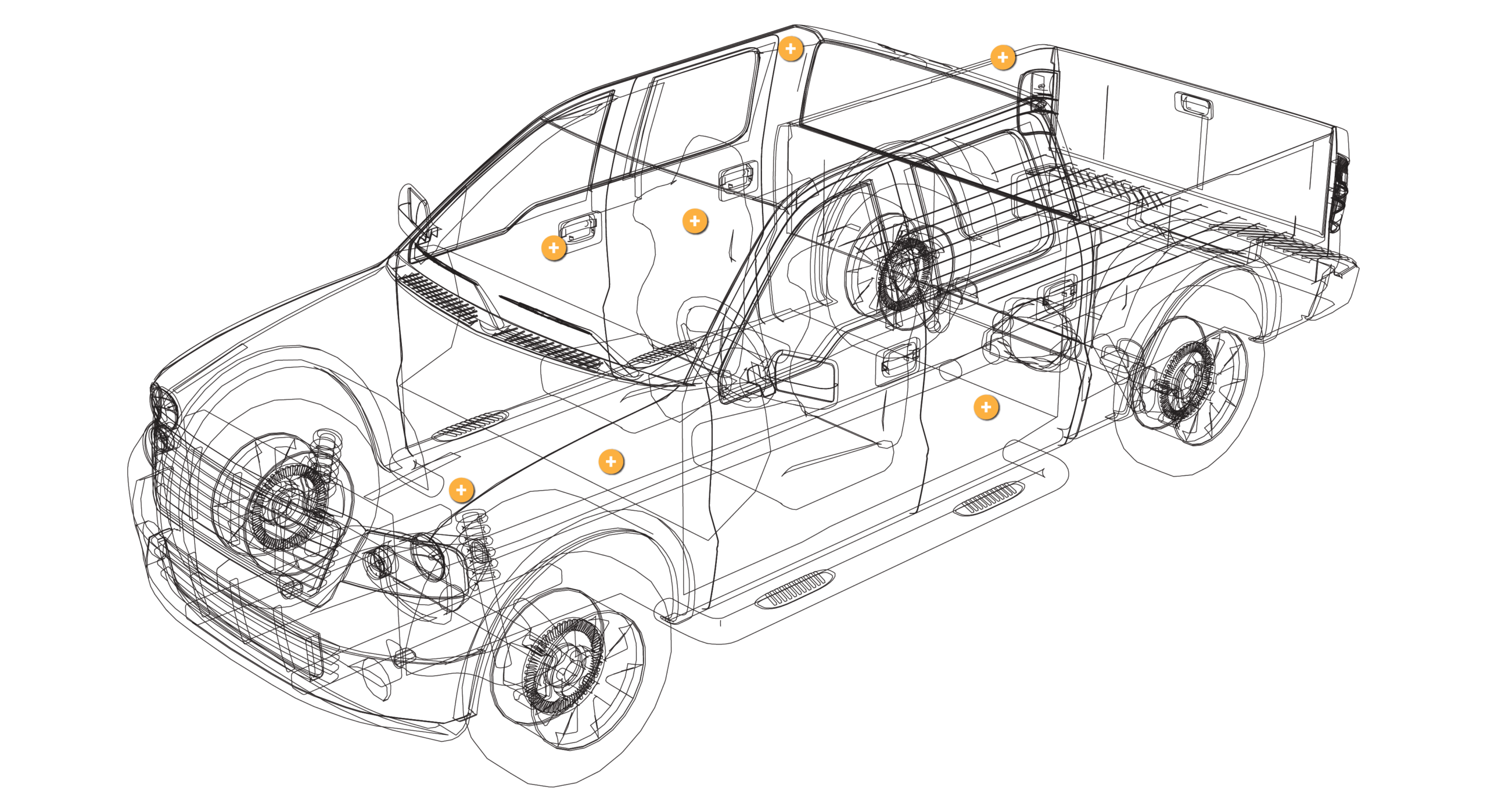

Cable and Wire Harness Management

Single and double-sided strap fastening solutions for wiring, harnessing, and cable systems. With a full in-house converting facility, Halco offers customized solutions to perfectly suit your application.

Floor Mats & Carpet Attachment

Woven and Molded hook fasteners providing a wide range of engagement strengths for a variety of different fabrics and loop materials in carpet and floor mat attachment applications.

Mounting & Interior Trim

Custom Hook and Loop solutions combined with specialty adhesives for low surface energy substrates, low fogging applications, etc.

Seating Assembly

Reclosable fasteners designed for use with sewing, cutting, welding, or mold-in technologies for seating applications.

Noise Reduction in Thermal & Acoustic Insulation

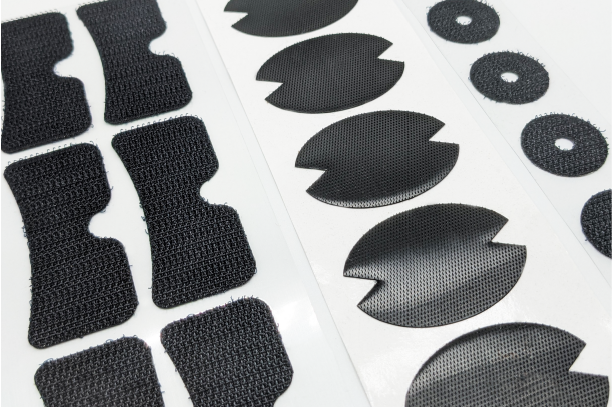

Specialty fasteners including custom adhesives and die cuts shapes for securing noise dampening materials inside vehicles.

Head Liner / Sunroof

Semi-permanent fasteners for headliners and sunroof applications. Designed and engineered for ease of application and installing.

Tonneau Covers & Bed Liners

Fastener attachment solutions for automotive accessories such as truck bed tonneau covers, soft tops, bed liners, seat covers, tire carriers, dashboard covers, and much more.

Case Study

Learn how Halco and 3M teamed up to reduce noise, vibration and harshness in electric vehicles

Automotive Adhesives

Halco offers a selection of 3M’s high performance adhesives that are low fogging, meet FMVSS302 flammability requirements and are specified by automotive OEMs for use in automotive interiors. These automotive adhesives work well on ABS plastics, foam, thermoformed rubbers and other materials without the use of primers.

Automotive Die-Cutting & strap Converting

Halco kiss cuts parts on a roll that are easy to remove and apply on a production line. Some die cuts can be integrated to a plastic part. We also fabricate custom automotive straps, strap parts and cable ties for securing seat covers, wire harnesses and charging cables, as well as accessories like jacks, wrenches and safety kits.

Request a Sample of Our Auto Hook and Loop Specialty Fasteners

Tell us a little about your project let us know if you need a Halco specialty hook and loop or 3M Dual Lock fastening solution to evaluate.

Specialty Automotive Fasteners

Halco’s comprehensive specialty product line has both general purpose products and a wide range or specialty products that solve unique design challenges. Here are some of the most common Halco hook and loop products sold into the automotive products market.

Auto Mushroom Hook

Our mushroom tape is often adhered to foam and used in the attachment of seat covers

Auto Mold-In Hook

Halco’s mold-In hook fasteners include both a shield-less and a gasket sidewall version for different seat designs.

Auto Loose Loop

Halco’s loose auto loop is suitable for automotive and aerospace seat trim applications.

Back-to-back strap tape

Halco’s Back2Back hook and loop strap tape is a bundling fastener to organize and secure cables, cords, and wire harnesses

Molded plastic hook

Our selection of molded hook is used to secure mats, cargo liners and soft trim

Applications

Seating & Covers

Halco helps automotive seat manufacturers attach seat covers to the foam by providing a loose knit loop fastener (Halco Auto Loop) that attaches to both mushroom and molded hook fasteners. This automotive loop product is supplied with industry standard stripes and meets fire retardant FMVS specs for a wide range of OEM specifications. Halco’s Woven Hook & Loop Fasteners are also a reliable choice for trim attachment & closure.

Floor Mats & Carpet

A variety of Halco hook and loop products are used to adjoin and seam sections of carpet in a vehicle. Die-cut hook and loop materials, often with automotive grade adhesive are used to secure floor mats and cargo liners.

Door Panels & Trim

Halco hook and loop is used to attach foam and acoustical insulation pieces in doors, roofs and other places in the vehicle for sound and vibration damping. Some interior trim panels can be attached using adhesive-coated hook and loop.

NVH (Noise, Vibration, Harshness)

Sound and vibration can be effectively reduced by attaching custom fit acoustical insulation parts around the entire interior cabin, including the floor and ceiling. This is also referred to as Buzz, Squeak and Rattle (BSR).

Wire Harness & Cable Management

Custom designed straps can be used throughout a vehicle to protect wire harnesses & secure items in load floors such as jacks & safety items.

Tonneau Covers & Aftermarket Accessories

Halco’s polyester hook and loop stands up to UV exposure, temperature and moisture and is a preferred solution for pickup bed covers. Other Halco hook and loop products are used in a wide variety of automotive aftermarket accessories such as soft tops, rooftop cargo carriers, bike carriers, electronic accessories, cargo management, and other products.

Automotive Clients