As the automotive industry recovers from recent challenges, the electric vehicle (EV) market is showing strong signs of growth. Driven by consumer demand for whisper-quiet rides, advanced technology, and zero-emission features, the future of EVs looks bright. However, the unique design of electric vehicles presents new engineering challenges, particularly in NVH reduction and managing BSR NVH (Buzz, Squeak, and Rattle).

Halco and 3M have joined forces to provide innovative solutions that help OEMs overcome these challenges, delivering improved acoustics and passenger comfort while simplifying the manufacturing process.

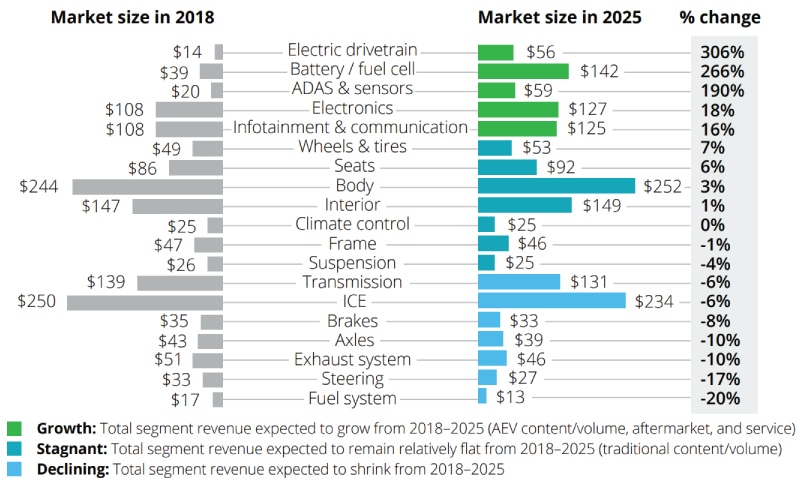

Projected segment market size

In billions, USD, 2018 vs. 2025

Source: Deloitte

The Challenge of NVH in Electric Vehicles

Electric vehicles (EVs) bring unique NVH challenges that differ from traditional internal combustion engine (ICE) vehicles. In ICE vehicles, engine noise often masks other sounds. In EVs, the absence of engine noise makes secondary sounds—such as high-pitched electric motor whines, cooling fan noise, and road vibrations—much more noticeable. This increased sensitivity to noise makes NVH reduction a critical focus for automotive engineers.

How to Reduce NVH in Cars

Reducing NVH in vehicles requires a systematic approach that addresses multiple noise and vibration sources, including:

|

|

|

|

|

|

|

|

|

|

|

|

By mitigating these elements, manufacturers can significantly enhance the quiet and smooth experience EV consumers expect.

BSR NVH and Engineered Materials

In addition to NVH, BSR NVH (Buzz, Squeak, and Rattle) is a common challenge in automotive design. Addressing these issues often involves the use of specialty engineered materials designed to dampen sound and vibration.

Engineered materials commonly used for NVH reduction include:

- Specialty Foams: Absorb sound and reduce vibration in passenger compartments.

- Nonwovens: Lightweight yet effective for acoustical insulation.

- Composite Materials: Provide both sound-dampening and structural benefits.

- Flock Materials: Help minimize squeaking and rubbing noises in tight spaces.

These materials are often shaped into smaller components to plug panel holes or mounted into brackets to reduce vibration. Alternatively, larger parts are manufactured to insulate entire sections, such as:

- Wheel guards and motor compartments

- Door panels

- Headliners

- Flooring panels and carpets

- Dashboards and tray systems

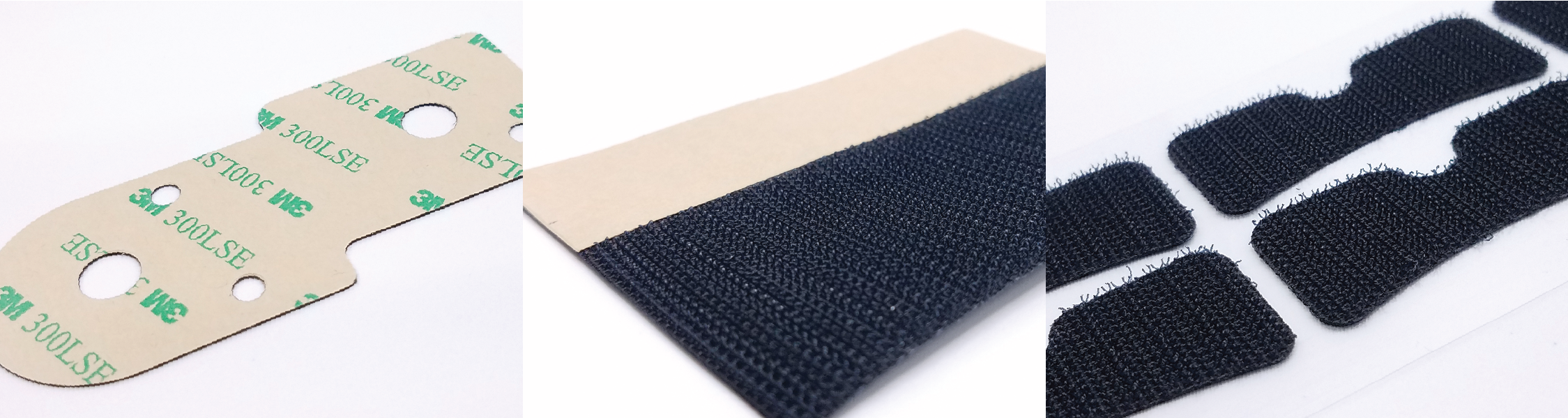

Halco and 3M: Attachment Systems for Insulative and Acoustical Materials

Insulative and acoustical materials play a crucial role in how to reduce NVH in cars, but effective attachment systems are just as vital. Halco’s advanced fastening systems and 3M’s high-performance adhesives ensure seamless integration of these materials into automotive designs.

Why Halco’s Custom Hook and Loop Solutions Stand Out:

- Quick and Simple Application: Peel-and-stick systems eliminate the need for complex tooling or hole alignment.

- High Productivity: Designed to meet the demanding production speeds of EV OEMs.

- Custom Die-Cuts: Tailored solutions for specific automotive parts, enhancing NVH and BSR mitigation.

Halco’s custom hook and loop solutions are enhanced with 3M adhesive tapes, like the 6038PC, to provide:

- Excellent bonding to porous, painted, and low-energy substrates.

- High initial tack for secure attachment during assembly.

- Resistance to high temperatures (-40°F to 250°F), ensuring long-term durability in automotive interiors.

A Proven Partnership for NVH Reduction

The collaboration between Halco and 3M offers a compelling solution for EV manufacturers and tier suppliers seeking effective NVH reduction. Key advantages include:

- Rapid Prototyping: Halco can deliver prototype parts within days, ensuring swift iteration and design optimization.

- Customized Solutions: Tailored fastening materials and adhesives meet specific NVH and BSR requirements.

- Proven Adhesive Technology: 3M’s automotive-grade adhesives are trusted for their superior performance in demanding environments.

This partnership empowers EV OEMs and tier suppliers to develop innovative solutions for how to reduce NVH in cars, ensuring a superior driving experience for end-users.

Driving Innovation in NVH Mitigation

At Halco, we’re dedicated to solving complex engineering challenges in the automotive industry. By combining our expertise in custom hook and loop solutions with 3M’s advanced adhesives, we provide manufacturers with tools to tackle BSR NVH and enhance the quiet, smooth ride EV drivers demand.

Have an NVH Challenge?

If you’re working on a project involving NVH reduction or BSR NVH, we’d love to help. Tell us about your needs, and we’ll provide a free sample kit tailored to your requirements. Together, we can create a quieter, more refined ride for your customers.

Tell us about your project and request our free design kit with hook & loop samples used in the automotive industry.