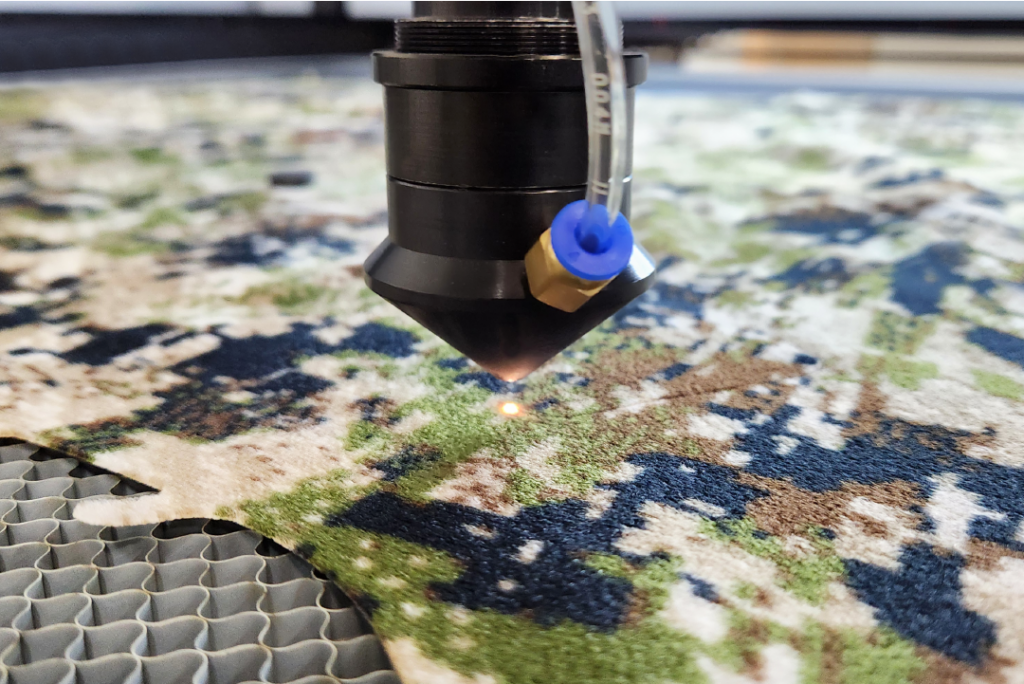

At Halco, our commitment to innovation and excellence drives us to continuously improve our manufacturing capabilities. Serving sectors such as aerospace, automotive, defense, medical, industrial, and display graphics, we’re proud to announce a breakthrough addition at our Hayward, CA facility—a state-of-the-art large format laser cutter. This cutting-edge equipment is transforming the way we deliver precise, high-quality die-cut parts and prototypes for our valued partners.

Transforming Die-Cutting with Advanced Laser Technology

Unmatched Precision and Efficiency

The integration of our new large format laser cutter is a game changer in our converting services. Designed for both speed and accuracy, this advanced technology offers two key benefits:

- Rapid Prototyping Without Traditional Dies:

Gone are the long waits associated with traditional rotary or steel rule presses. With our laser cutter, designers can quickly produce prototypes directly from digital drawings. This streamlined process not only shortens development cycles but also allows for rapid iterations, ensuring your product designs can evolve with precision and speed.

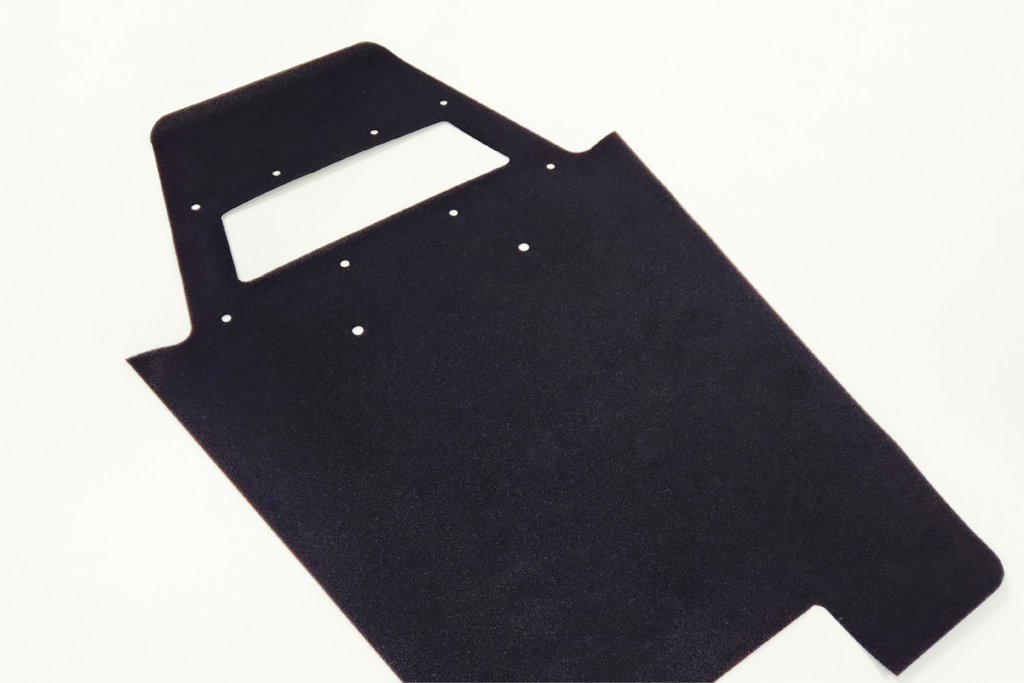

- Capability to Handle Large Format Die-Cuts:

Unlike conventional rotary presses, our laser cutter isn’t confined to small, standard sizes. Its ability to handle large format die-cuts means you now have greater flexibility. Whether your project demands oversized parts or intricate, detailed designs, our equipment delivers exceptional results that meet your exact specifications.

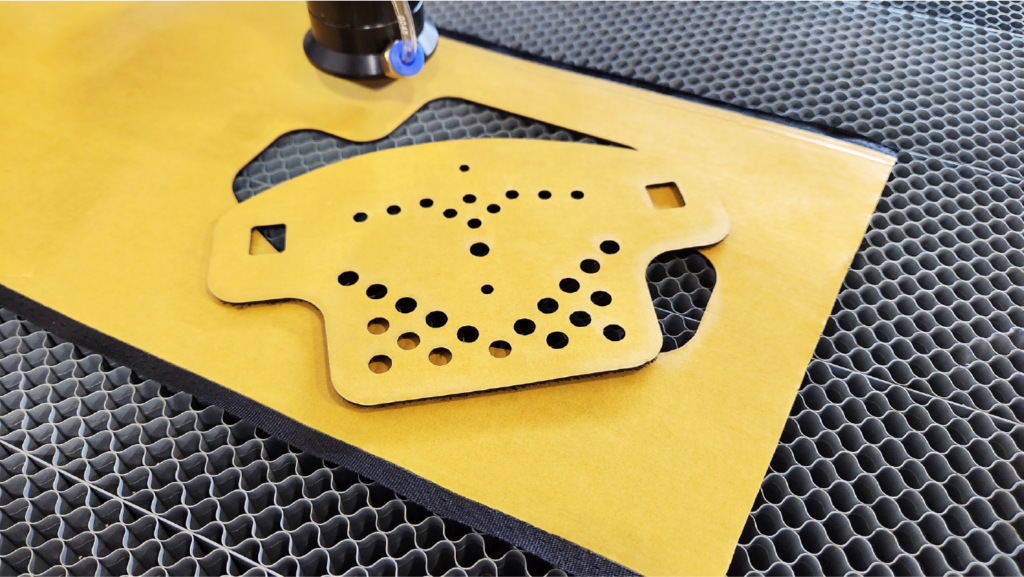

How It Works: Vacuum Precision Meets Laser Accuracy

The secret behind the incredible performance of our laser cutter lies in its innovative design that combines vacuum precision with laser accuracy:

Why This Matters to You

- Secure Material Holding: Before the cutting process begins, the laser cutter uses vacuum pressure to firmly secure materials. This stable hold minimizes any movement during cutting, ensuring that every cut is crisp and accurate—even for the most delicate or complex designs.

- Precision Laser Cutting: The laser swiftly and smoothly cuts through materials, reducing waste and maximizing production efficiency. This process not only guarantees high-quality parts but also allows for tight tolerances and repeatable consistency, making it ideal for both prototyping and final production runs.

- Collaborative Development:Our team works closely with customers to finalize part drawings, ensuring that the programming of the laser cutter precisely matches your design requirements. This collaborative approach helps bridge the gap between concept and production, resulting in products that perform exactly as envisioned.

Why This Matters to You

By incorporating this advanced laser cutting technology, Halco is poised to support you at every stage of product development—from the initial design and prototyping phases through to production and beyond. The benefits include:

- Faster Time-to-Market:

Rapid prototyping accelerates the design process, allowing your team to innovate and launch products faster than ever before. - Enhanced Flexibility:

The ability to produce large, intricate die-cuts means your design possibilities are virtually limitless. Customize your parts to perfectly align with your project needs. - Improved Quality and Efficiency:

With precise control over each cut, you can expect reduced material waste and superior part quality. Our laser cutter’s efficiency also means lower production costs and higher operational throughput. - Seamless Integration with Halco’s Expertise:

Whether your project involves specialty hook and loop materials, pressure-sensitive adhesives, or complex assemblies including webbing, foam, or elastic, our team is here to partner with you. We combine our advanced technology with deep industry knowledge to deliver tailored solutions that meet your unique challenges.

Let’s Connect on Your Next Project

If you’re interested in exploring how our new large format laser cutter can transform your product development or if you’d like to discuss your specific project requirements, we invite you to reach out. Our dedicated sales and technical representatives are ready to collaborate and demonstrate how this innovative technology can be integrated seamlessly into your operations. Contact your Halco representative today to request a consultation or test out our prototypes—we’re excited to help you unlock new possibilities in rapid, precise die-cutting.

Innovation in Every Cut

Halco’s new large format laser cutter is more than just a piece of equipment—it’s a powerful tool that redefines the future of die-cutting. Offering rapid prototyping, expansive cutting capabilities, and unmatched precision, this technology is set to revolutionize the way you bring products to market. With faster turnaround times, enhanced design flexibility, and improved quality control, you can approach your next project with confidence and agility. Let Halco’s expertise and advanced laser technology help you achieve excellence in every cut.

For more details on how our new laser cutter can elevate your production processes, don’t hesitate to connect with us. Together, we’ll shape a future of innovation and success.