Adhesive-backed hook and loop fasteners are a simple yet powerful addition to product designs. By incorporating a “peel and stick” backing, these fasteners offer a recloseable, reliable attachment that can transform everything from interior signs to access panels on appliances. Used across a wide range of industries—from medical and automotive to sports, fitness, industrial, display, and graphics—the versatility of adhesive-backed hook and loop continues to expand as designers seek easy, efficient fastening solutions.

Enhancing Product Design with Adhesive-Backed Fasteners

The convenience and effectiveness of adhesive-backed hook and loop fasteners lie in their ability to provide a secure attachment without additional hardware. For example, a simple interior sign can be mounted with self-stick hook and loop circles, while an industrial manufacturer may rely on sticky back tape to attach an access panel to an electrical enclosure. The beauty of these fasteners is that they streamline assembly and create clean, reconfigurable connections while maintaining aesthetic appeal.

Challenges in Finding the Right Adhesive-Backed Fastener

Engineers have several options when selecting an adhesive-backed hook and loop fastener. One common route is to choose from standard adhesive options offered by multinational brands such as Velcro® or YKK. While these products work well for general-purpose applications, they might not perform optimally with challenging substrates or meet the specific demands of specialized industries. Many of these standard adhesives come with limited options, and relying solely on third-party products may not always yield the best results for niche applications.Another approach is to work with specialty converters that focus on adhesive tape converting. However, these converters may not have the deep expertise in hook and loop materials or understand the unique nuances required for different industrial applications. This gap in experience can lead to solutions that might not fully address customer needs, particularly when specialized adhesive performance is critical.

The Halco Difference: Expertise and Customization

Halco stands apart as an industry and materials specialist converter, committed to developing custom solutions that seamlessly integrate hook and loop fasteners with pressure-sensitive adhesives. Here’s how we differentiate ourselves:

Tailored Solutions for Any Application: Whether your project is in the automotive, medical, defense, or other markets, we understand that different substrates—like low surface energy plastics, powder-coated paints, vinyl, or PVC—require adhesives with unique properties. Our team works directly with customers to determine the best adhesive option, whether for heat-welded assemblies or stitched constructs, ensuring optimal performance.

Specialized Expertise: We focus exclusively on hook and loop fasteners and adhesive solutions, giving us a deep understanding of the technical and performance challenges across multiple industries.

Broad Adhesive Portfolio: Halco offers a range of standard pre-coated adhesive options alongside custom adhesive solutions. Our offerings include proven 3M laminated adhesive tapes, such as the 3M 300LSE adhesive, which have been trusted for decades in various applications..

Making the Right Choice with Halco’s Adhesive Selection Guide

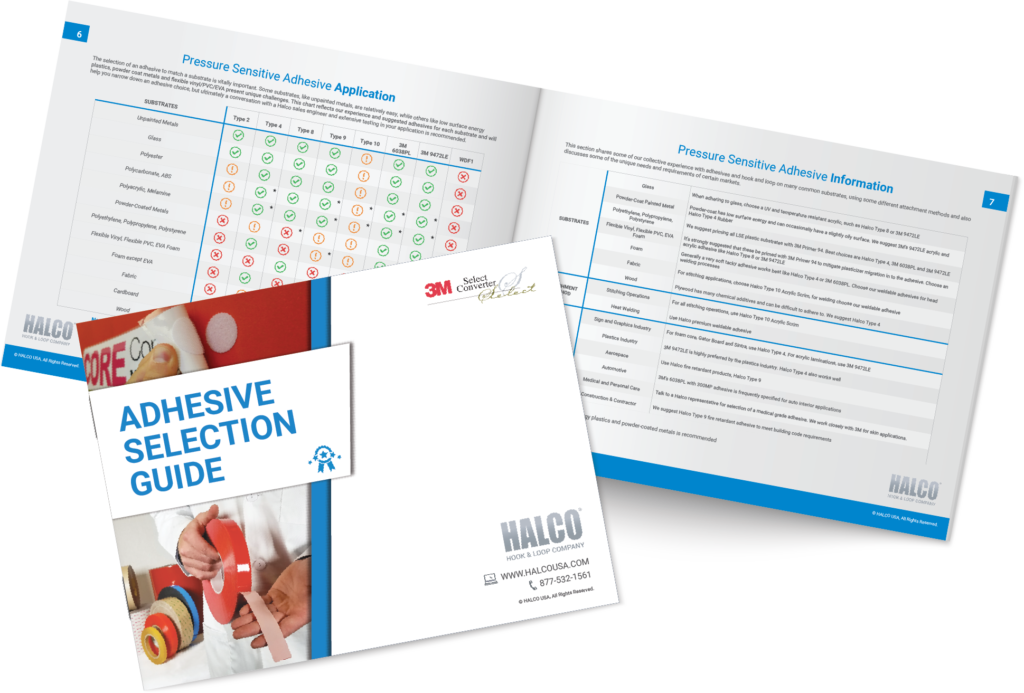

Choosing the right adhesive is often a complex decision that involves understanding your application’s materials, processes, and performance requirements. To help engineers and product designers make informed decisions, we have developed the Adhesives Selection Guide. This comprehensive resource provides:

- Performance Data: Key specifications and test results for both our pre-coated adhesive options and custom laminated solutions, including those from our 3M Select Converter lines.

- Substrate Recommendations: Tailored suggestions for which adhesives work best with different substrates and manufacturing processes, helping to ensure a consistent and reliable bond.

- Process Compatibility: Insights into the optimal installation methods, whether your assembly uses heat welding, stitching, or other techniques.

The best way to determine the most suitable adhesive option is to speak directly with a Halco Sales Engineer. With decades of experience in hook and loop applications, our experts will walk you through your project’s specific requirements, offer tailored recommendations, and send you samples to test under real-world conditions.

Experience the Halco Advantage

At Halco, we believe that the right fastening solution can simplify production, enhance product performance, and elevate design. Our adhesive-backed hook and loop fasteners are engineered to meet the highest standards, providing secure, easy-to-use options that integrate seamlessly into your manufacturing process.

Whether you’re developing a new product or improving an existing design, our extensive range of adhesive options and our unwavering commitment to quality ensure that you receive a solution perfectly suited to your needs. For expert advice or to request samples, reach out to a Halco Sales Engineer today and experience the difference that our specialized approach can make.